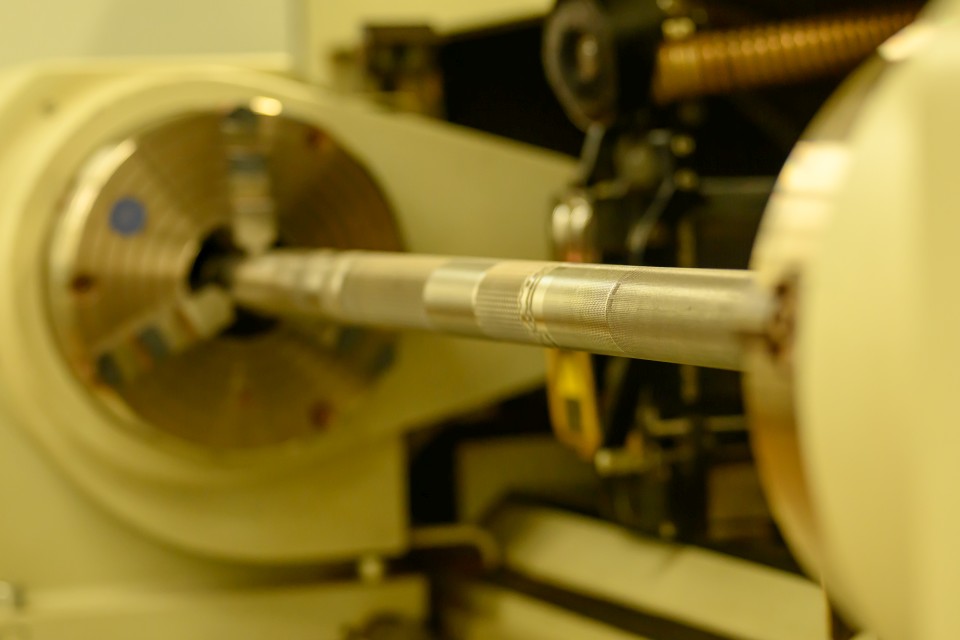

Engraving of embossing rollers

Our processes:

- Pure digital high-pulse direct structuring (LASER)

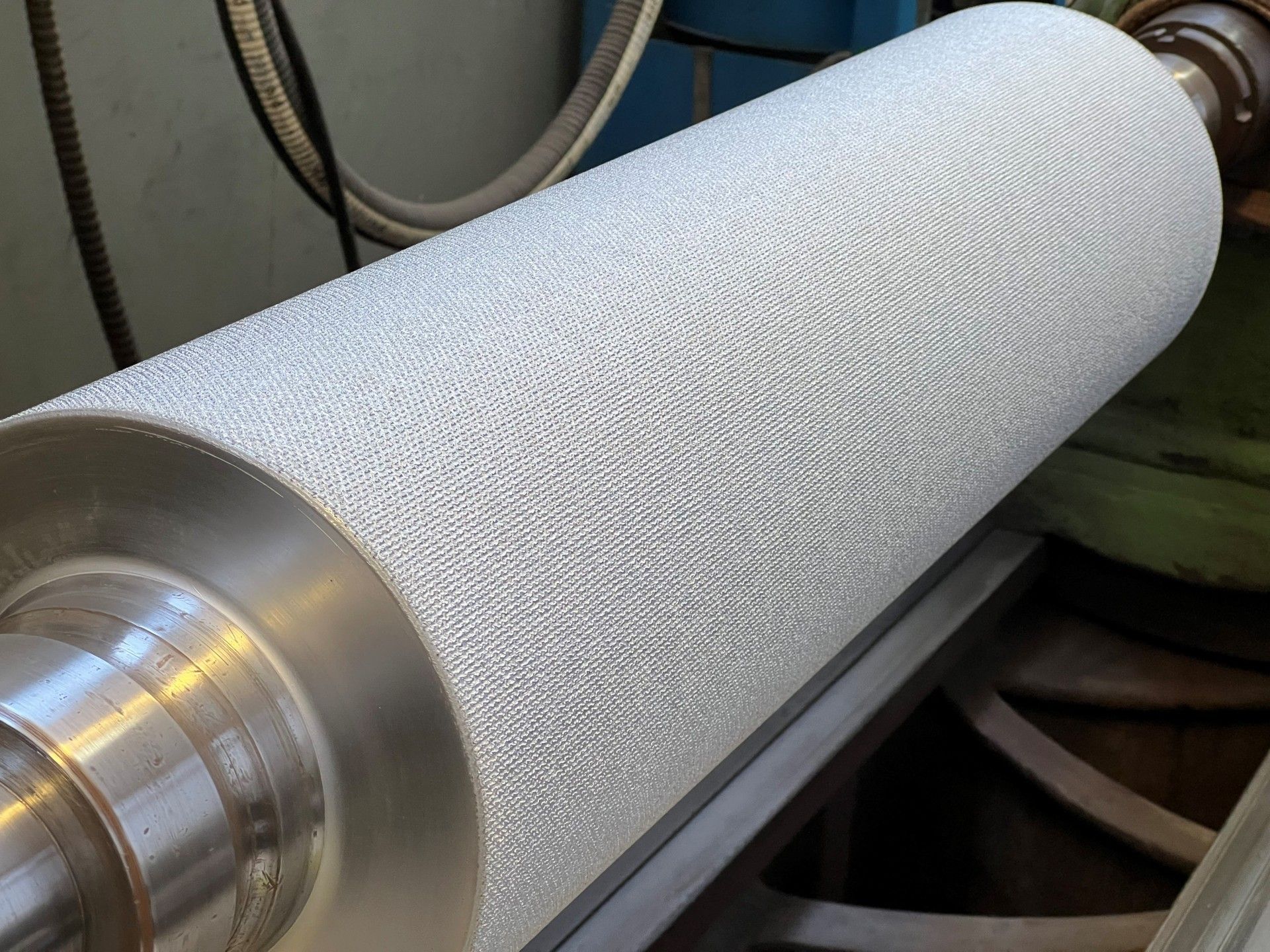

- Surface treatment (brushing / blasting)

- Autotype etching process (special depths + refinements + special screen)

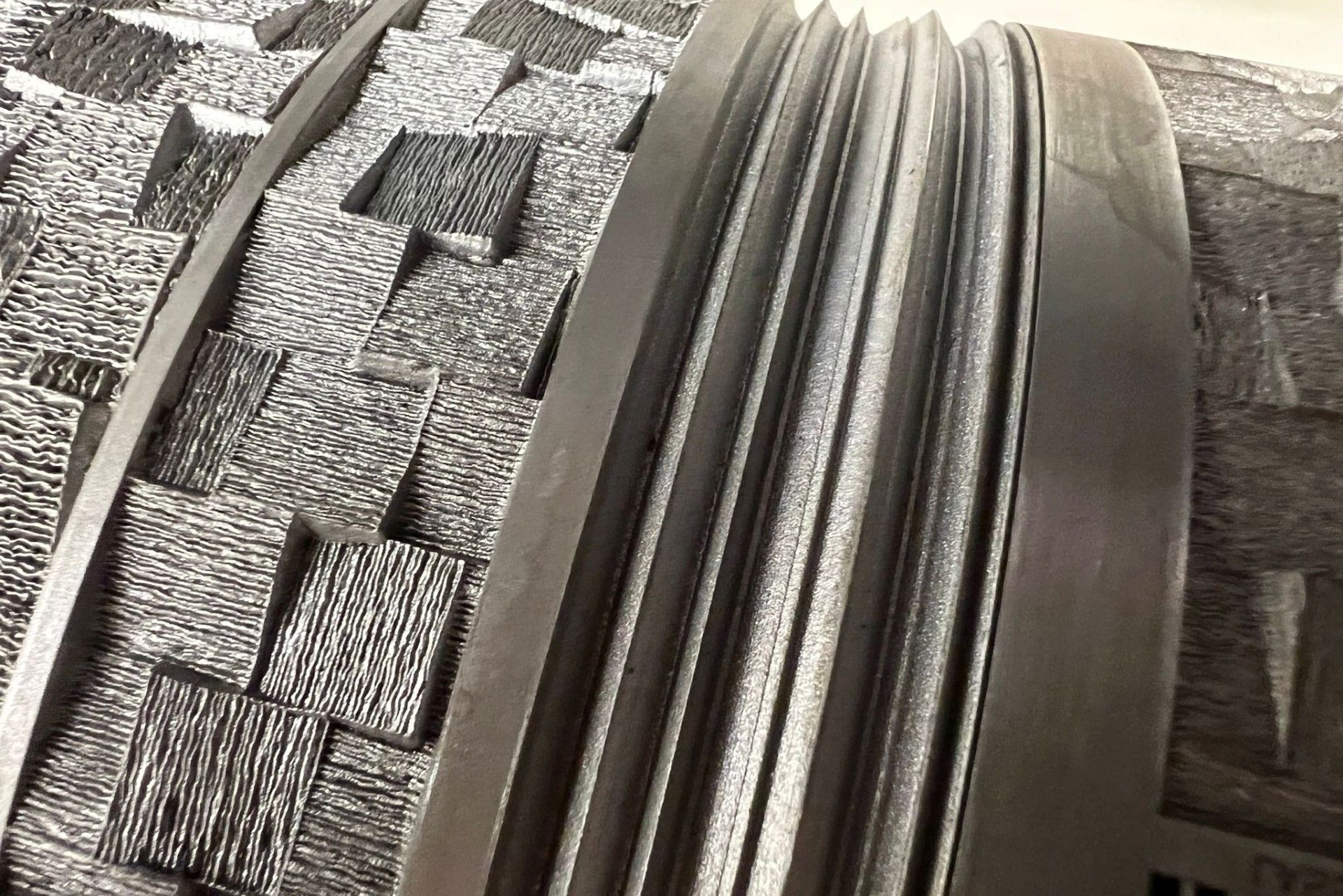

- Hand-Engraving

- In-House Chroming

–> Perfect precision for impressive results!

Engraving of embossing rollers

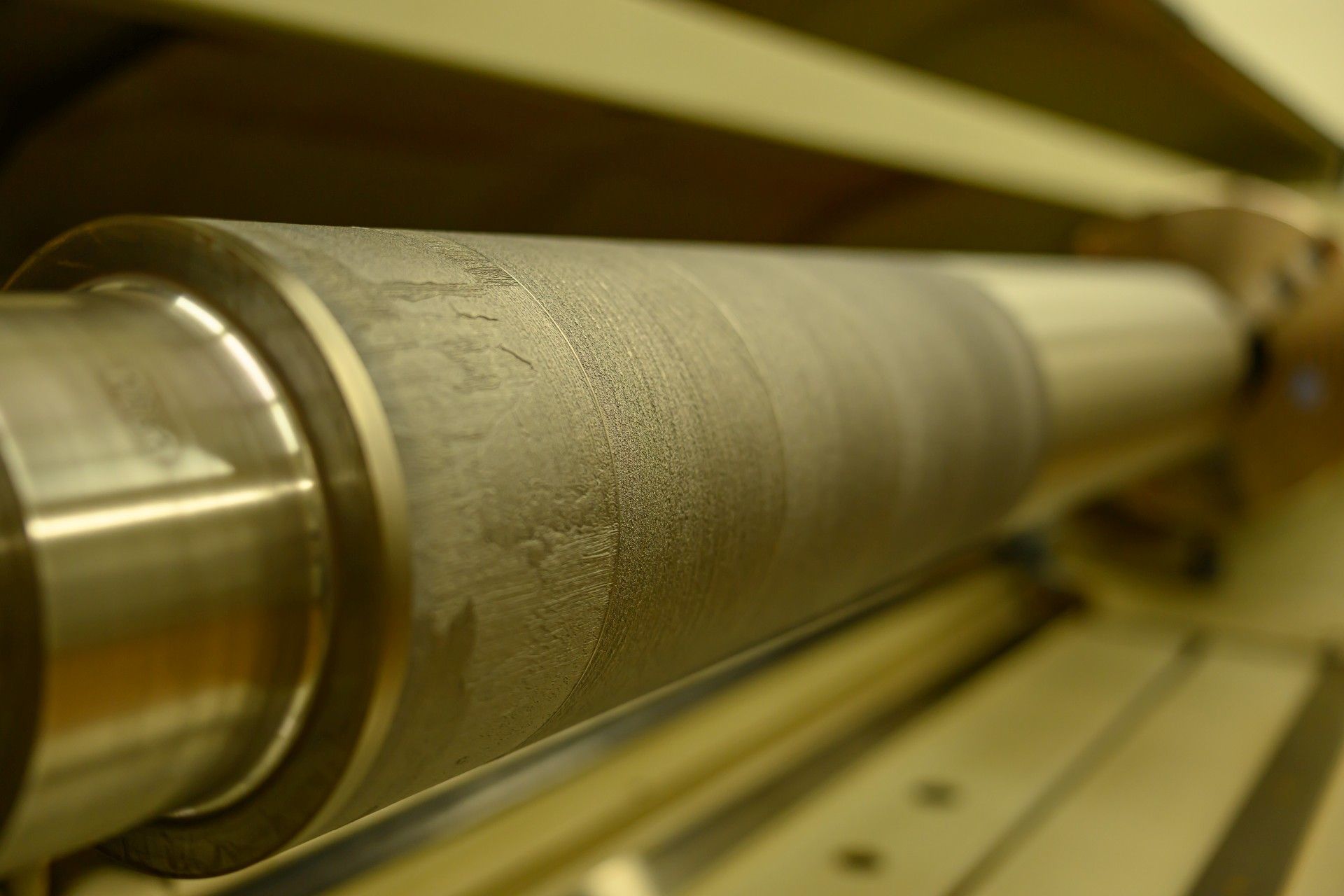

The engraving of embossing rollers is a traditional process that has been used for many decades. Special tools are used to engrave the desired pattern on the surface of the roller. This process is suitable for the rotary embossing and shaping of a wide variety of materials. The embossing rollers can be manufactured in different sizes and shapes and enable high precision in the realization of the embossing shape.

The embossing rollers are manufactured using state-of-the-art laser processes or, if required, using conventional layer etching processes and surface treatment by sandblasting or brushing (...).

The digital laser process is the most modern method for engraving steel or copper surfaces. A powerful high-pulse laser beam is used to engrave the desired pattern directly into the surface of the metal. Finally, a chrome layer is applied to ensure the durability of the embossing roller. The laser process offers maximum precision and lateral uniformity. It enables the engraving of very complex patterns and almost any structure and can be reproduced very precisely

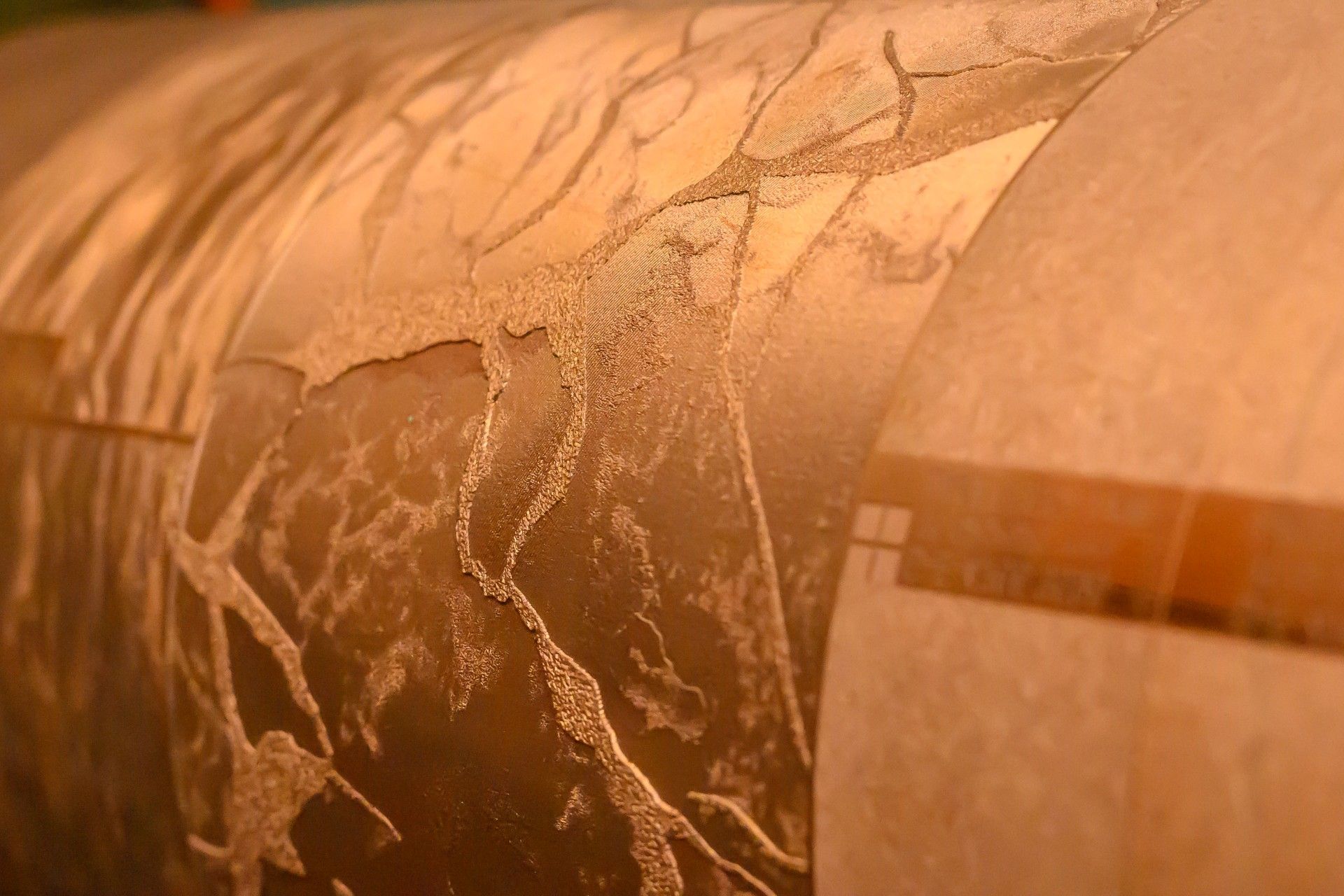

The etching process is based on chemical reactions to create the desired pattern on a surface. A protective layer is applied to the material (masking) and an acid acts on the unprotected areas. The acid attacks the material and creates an indentation as a mold cavity in the surface of the roller and, when used in the machine, the desired pattern when pressure is applied to the layered web to be embossed. By repeating the process several times depending on the desired depth, the three-dimensional pattern is worked out. The etching process is particularly suitable for processing metal surfaces where high engraving depths are required. It can also be used to create special grids on roller surfaces.

Embossing is suitable for a variety of materials such as paper, leather, glass, plastics or metal and Aluminum in the packaging, wallpaper, furniture decoration and automotive industries, for example.

The so-called "in-register" embossing, i.e. the precisely fitting combination of printing cylinder and embossing roller, gives the printed products a high-quality look and feel, as the embossed pattern is clearly visible and tangible and is precisely positioned with the printing of the colors.

In addition, embossing can also serve as a protective function to prevent counterfeiting or improve the durability of the product.

An art that has become very rare, but is still highly valued at Sügravo, is hand engraving, the most demanding form of embossing roller production in terms of qualification. Experienced and highly trained specialists with many years of experience produce manually processed embossing rollers using a wide variety of tools. This type of processing gives the rollers a special individual shine that could not be imitated by conventional laser processes.

Furthermore, this specialist knowledge and the specially designed workshop equipment enable selective roller repairs. If you wish to repair a defect or deeper damage to one of your rare and valuable roller surfaces, please do not hesitate to contact us. Our experts will be happy to take a look.