Electromechanical engraving of gravure cylinders

From electroplating baths and precise polish mastering to the perfect surface finish after chrome plating in our in-house baths. High-quality copper engravings for gravure cylinders of various sizes.

Engraving of gravure cylinders

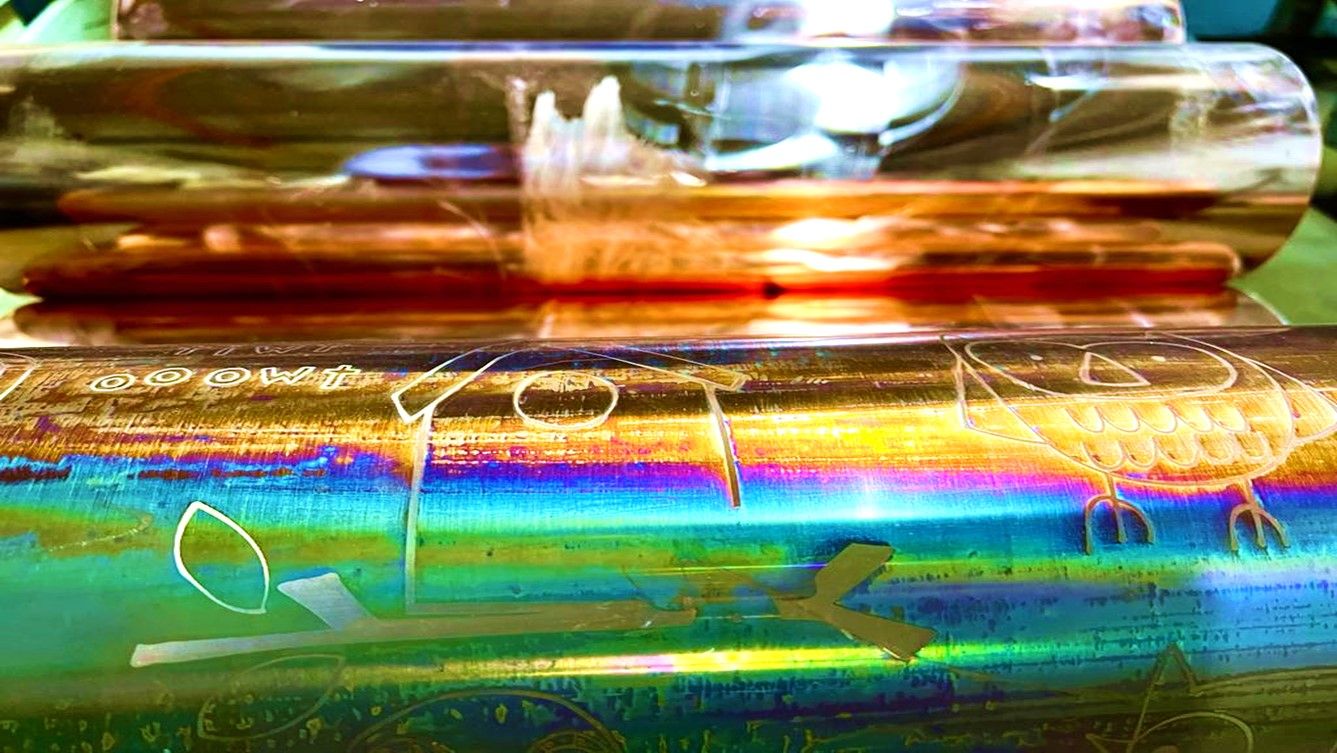

Engraving gravure cylinders is a process for ensuring consistent quality in large print runs, in which the desired print image is engraved into the surface of the cylinder by the repro department. This cylinder is then used in the printing press to transfer the image onto a paper web (print substrate). The motif areas in the engraved cells are filled by dipping, reduced to a controlled minimum size using an ink squeegee and then transferred to the substrate by a rotary contact process (printing). Engraving requires precision and expertise in order to produce a clear and sharp print image and ensure correct coloring.

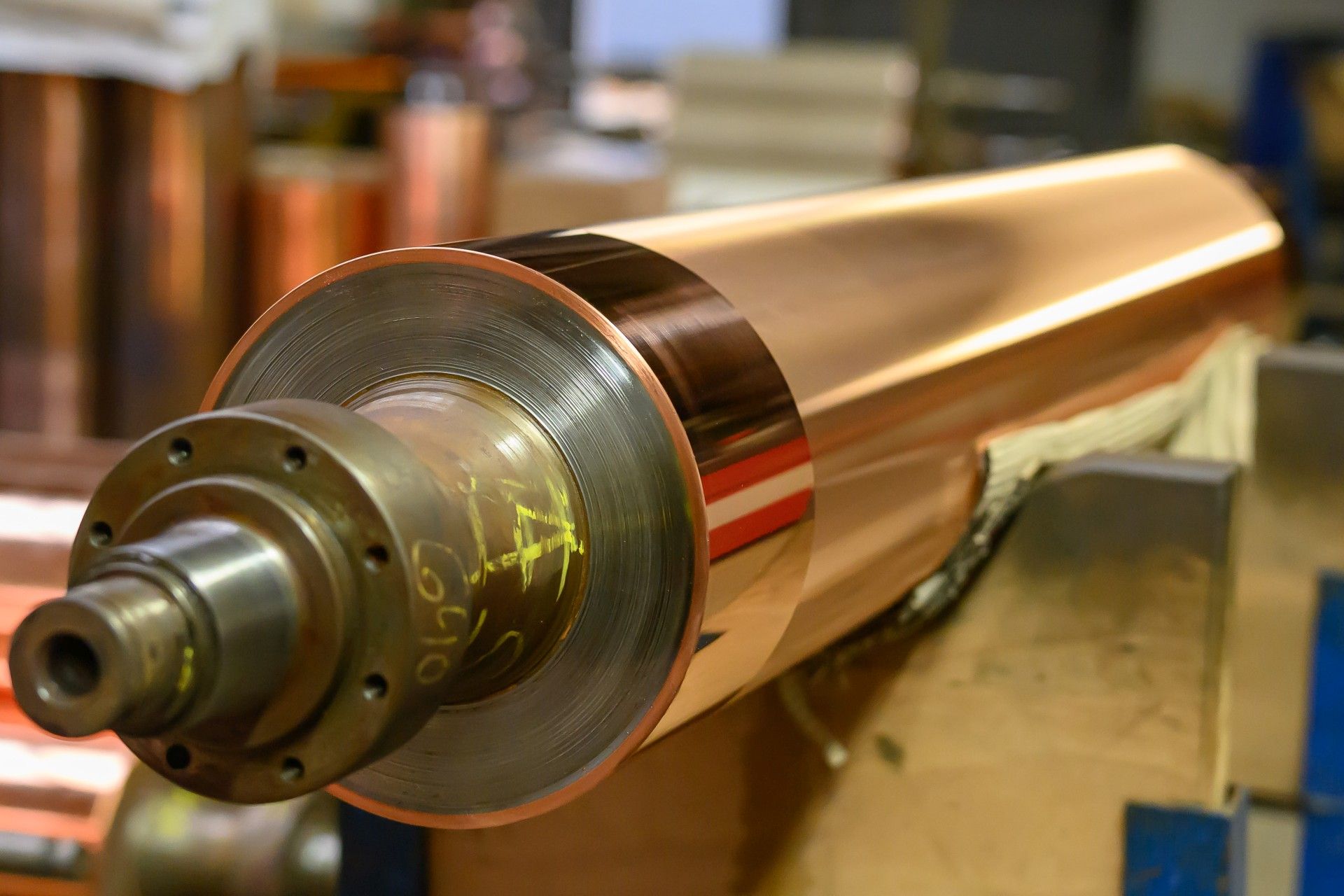

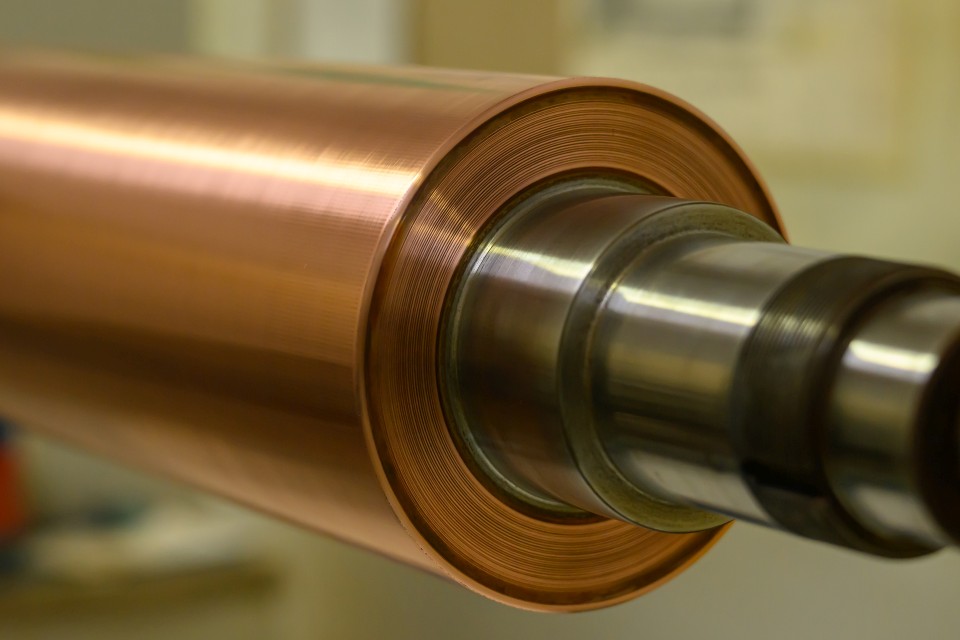

The gravure cylinder is nickel-plated, copper-plated and chrome-plated in our in-house electroplating department, which ensures a high overall quality of shape and precise detail. This is the prerequisite for engraving with a clear and detailed representation in the printing process.

Copper plating is carried out using chemical electroplating baths that meet the high environmental requirements for process safety and environmental regulations and requires precise control of the process parameters in order to achieve the desired quality. Only a uniform metal coating and clean engraving ensure a clear image and high color accuracy during printing.

If you require high-quality gravure cylinder engraving, it is advisable to turn to an experienced service provider like us. Only a professional provider will have the necessary expertise and state-of-the-art technologies to meet your requirements and provide you with high-quality printed products.

To summarize, gravure body production, electroplating and surface finishing are important steps for print quality and reliability in gravure printing. Only through precise engraving techniques and accurate control of the electroplating process can high quality print products be achieved.